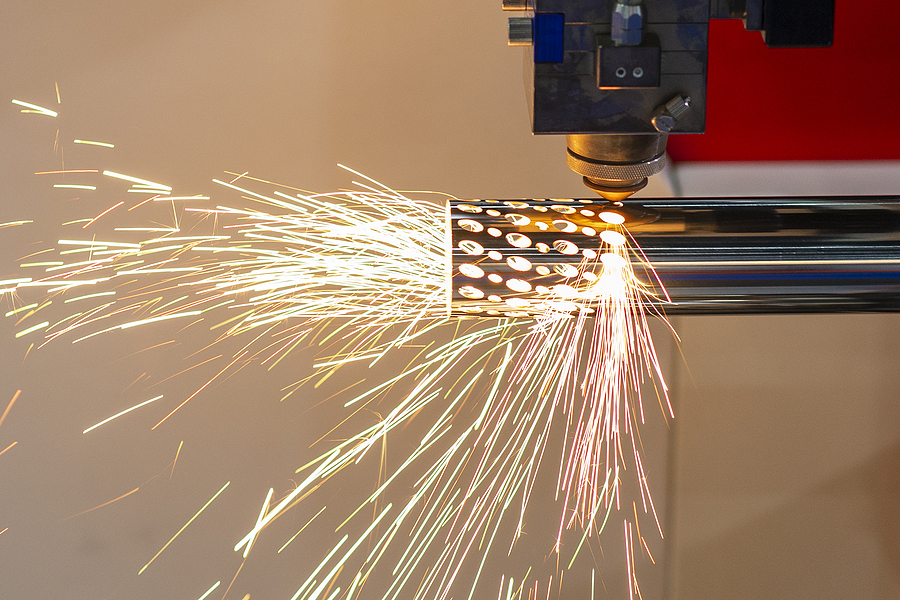

While a laser cutter is a wonderfully useful and versatile tool for any workbench or studio, there are always inherent risks that are associated with the use of them. Like any piece of machinery, there needs to be some level of respect when it comes to the use and subsequent care and storage of the tool to ensure that safety requirements are maintained. This is not only applicable to a laser cutter, but to any tool you find in your workspace that requires a careful and considered approach.

The humble machine has been used for a great many things in our day-to-day lives that don’t often get thought of, from precision slicing of material to engraving on softer materials, they have a wide range of power capacities and sizes to choose from as well. Regardless of size or capacity, there should always be the following safety measures put into practice for your laser cutter.

1. Proper PPE

The foremost safety measure to be utilised for your laser cutter should of course be the proper PPE, otherwise known as personal protective equipment. This is standard for a majority of the tools that require power and exude a great deal of energy in their use, in this instance there should always be some form of safety goggle being employed by the user to ensure matter and dangerous light does not cause irreparable damage to the eye. Proper hand protection is also a wise move to ensure there is a reduction in potential accidental burning.

The level of PPE you require will depend on the laser cutter model and its veritable strength, so it’s best to consult professionals before use to ensure you have the right PPE for the job.

2. Training In Proper Usage

Having proper training in the correct use of the laser cutter is an essential aspect to ensuring safety is maintained throughout. This can be attained through various courses offered by the manufacturers of the machines themselves, as well as industry professionals who offer their services and qualified trainers. Having the adequate and proper education in how to use a laser cutter will pay off wildly in the long run, allowing you to properly understand the inner workings of the machine as well as increasing your proficiency in the usage.

3. Clean Working Environment

Having a clean working environment is a must for ensuring the safety of your workspace, not only for obvious tripping hazards but also for the integrity of the atmosphere of your workspace. The tripping hazards are one thing, it also helps to ensure there are no dangerous hanging objects that can interfere or distract from focusing at the task at hand which is essential for any heavy machinery operation, especially a laser cutter.

4. Emergency Provisions

Any workspace containing a laser cutter, or any type of machinery that has imminent danger with misuse should contain at least the basic provisions for emergencies. This includes signage that indicate the necessary PPE to be worn at all times for those coming into the workspace, a first aid kit in case of an emergency involving the laser cutter, as well as a safe area marked off for others in the vicinity to have a safe distance. These small but vital additions to the workspace will increase the safety of the workspace exponentially.

Using the tool for its intended purpose is only one small step towards a safe working environment, by taking the necessary precautions and training, you’ll have no issue with safely utilising your new laser cutter.